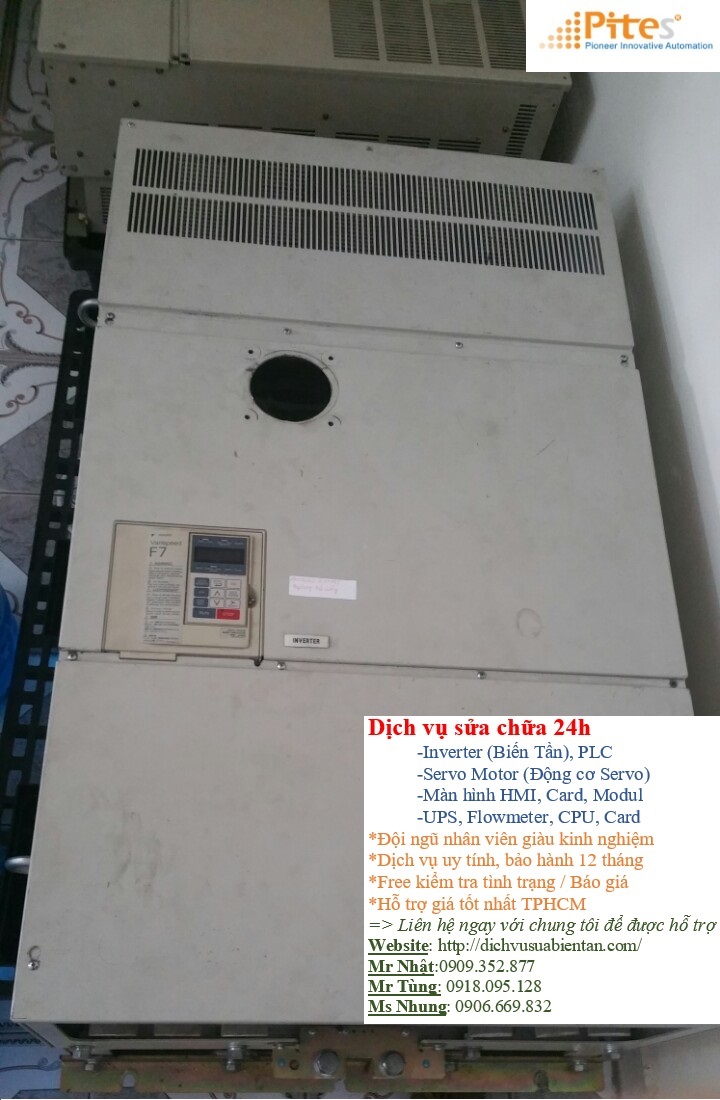

Sửa chữa - Tư vấn cung cấp mới biến tần Bonfiglioli ( ANG Series) chính hãng uy tính

Hãng sản xuất: Inverter bonfiglioli vectron

Dịch vụ sửa chữa, bảo trì - bảo dưỡng, tư vấn thay mới biến tần của hãng Bonfiglioli

Specifications

-

Main options

Optional Keypad for easy setup, commissioning, parameterization, copy function and diagnosis

• KP500: Removable keypad

• KPCMK: Cabinet mounting kit and handheld for keypad

Optional Interface for communication to PC

• KP232: Serial communication interface, which can be mounted & unmounted during operation, recommended for service personnel

• ISO-USB: USB to Serial adapter, galvanic decoupled

Variants Automation Interface

• EM-AUT-01: EtherCAT® and Encoder evaluation (TTL, HTL, Resolver, Hiperface, EnDat 2.1)

• EM-AUT-04: EtherCAT® and encoder evaluation (HTL, Resolver)

• EM-AUT-11: PROFINET and Encoder evaluation (TTL, HTL, Resolver, Hiperface, EnDat 2.1)

• EM-AUT-21: Ethernet/IP and Encoder evaluation (TTL, HTL, Resolver, Hiperface, EnDat 2.1)

• EM-AUT-31: Varan and Encoder evaluation (TTL, HTL, Resolver, Hiperface, EnDat 2.1)

Optional PC Software

• VPlus for Windows with setup, terminal monitor

• Actual value window

• Scope function

• Parameter Storage

Accessories:

• Brake Reistors Type BR: The Brake resistors offer an inexpensive solution to dissipate generatoric power, which occurs at the deceleration. A thermal sensor for the brake resistor protects the resistor from overheating.

• Mains Chokes Type LCVS & LCVT: Mains Choke types LCVS (for single mains phase installation) and LCVT (for three mains phase installation) increase the overvoltage protection of the inverter and increase the EMC of the system.

• Mains Filters Type FTV: Depending on the application boundaries certain EMC levels have to be achieved. The Mains filters are a component to improve the EMC behaviour in a machine installation. -

Degree of protection

IP20 (EN 60529)

-

Certifications

UL508c

STO (EN13849 / EN 61508) -

Power supply & Power range

ANG410: 0.25 - 400 kW / three-phase 360 - 480V / 50 - 60 Hz (± 10%)

Parallel connection up to 1200 kW

ANG210: 0.25 - 9.2 kW / single or three-phase 200 - 240V / 50 - 60 Hz (± 10%)

ANG510:160 - 400 kW / three-phase 525V / 50 - 60 Hz (± 10%)

Parallel connection up to 1200 kW

ANG610: 160 - 400 kW / three-phase 690V / 50 - 60 Hz (± 10%)

Parallel connection up to 1200 kW

Control of asynchronous and synchronous motors.

Control methods:

• V/f

• Field-oriented control with encoder

• Field-oriented control without encoder

Overload capacity:

• 100 % continuous output

• up to 150 % for 60 s

• up to 200 % for 1 s

Switching frequencies 2,4,8,12,16 kHz (availability depending on power size)

EMC filter integrated up to 9.2 kW (EN61800-3) -

Software features

Main software features

• Positioning function via field bus (Motion Control compatible to CiA DS402)

• Rotary table control

• Master/slave function with electronic gear

• Power failure regulation

• Function for lift, crane and winch applications

• Spindle control

• Traverse function for winders

• Programmable reference value channel

• Programmable start and stop characteristics

• Motor potentiometer

• Programmable S curve

• 4 data sets

• Auto startup and commissioning

• Auto reset after failure

• Auto start after power failure

• PI controller

• Volume flow control

• Jerkfree torque/speed changeover

• Mechanical brake control free of friction

• Index control

• Intelligent current limits

• Comprehensive monitoring and protection capabilities

• High-speed control

• 3 different brake management functions -

Hardware features

Integrated safe torque off (STO SIL 3 / PL e) function

• External 24Vdc supply

• Integrated dynamic braking module

• DC link connection

• Various feedback sensors

• Encoder interface for Resolver

• Cubic interpolation

• Motor temperature monitoring

• Plug-in power terminals (up to 3kW)

• Plug-in and programmable control terminals

• 6 digital inputs, 1 multifunction input

• 1 digital output, 1 multifunction output

• 1 relay output (changeover contact) -

Mounting options

Optional keypad for easy setup, commissioning, parameterization, copy function and diagnosis

• KP500: Removable keypad

• KPCMK: Cabinet mounting kit and handheld for keypad

Optional interface for communication with PC

• KP232: Serial communication interface that can be mounted & unmounted during operation, recommended for service personnel

• CM232: Serial communication interface that is installed during commissioning, recommended for continuous data logging or data exchange

• CM485: Serial communication interface that is installed during commissioning, recommended for continuous data logging or data exchange

• ISO-USB: USB to serial adapter, galvanic decoupled

Optional field bus communication:

• CM-CAN: CANopen

• CM-PDP: PROFIBUS

• CM232: Modbus ASCII & Modbus RTU for point-to-point connection

• CM485: Modbus ASCII & Modbus RTU via RS485 connection

• CM-DeviceNet: DeviceNet

• CM-EtherCAT®: EtherCAT®

• CM-PROFINET: PROFINET

• CM-Ethernet/IP: Ethernet/IP with one usable port as end-of-line device

• CM-Ethernet/IP-2P: Ethernet/IP with two usable ports (daisy chaining is possible)

• CM-Modbus/TCP: Modbus/TCP with one usable port as end-of-line device

• CM-Modbus/TCP-2P: Modbus/TCP with two usable ports (daisy chaining is possible)

• Ethernet VABus/TCP: VABus/TCP: with one usable port as end-of-line device

• Ethernet VABus/TCP-2P: VABus/TCP: with two usable ports (daisy chaining is possible)

Optional I/O Extension:

• EM-IO-01: Expansion for 3 digital inputs, 2 relay outputs, 1 analog input, 1 analog output, system bus connection, DC 24 V power supply output

• EM-IO-02: Expansion for 3 digital inputs, 1 relay output, 1 analog input, 1 analog output, motor-PTC input, system bus connection, DC 24 V power supply output

• EM-IO-03: Expansion for 2 digital inputs, 1 relay output, 1 analog input, 2 analog outputs, motor-PTC input, system bus connection, DC 24 V power supply output

• EM-IO-04: Expansion for 2 digital inputs, 1 digital port (input or output), motor-PTC input, system bus connection, DC 24 V power supply output

Optional encoder & feedback evaluation:

• EM-ENC-01: TTL/HTL encoder input (2 channels), encoder emulation output (2 channels), 1 analog input, system bus connection, DC 5 V power supply output

• EM-ENC-02: TTL/HTL encoder input (2 channels), 1 digital port (input or output), 1 analog input, 1 analog output, system bus connection, DC 5 V power supply output

• EM-ENC-03: TTL/HTL encoder input (2 channels), system bus connection

• EM-ENC-04: TTL/HTL encoder input (3 channels), 1 relay output, 1 analog input, 1 analog output, 24 V power supply output, DC 5 V power supply output

• EM-ENC-05: TTL/HTL encoder input (3 channels), 1 analog input, 1 analog output, system bus connection, 24 V power supply output, DC 5 V power supply output

• EM-RES-01: Resolver input, encoder emulation output (2 channels), 1 analog input, system bus connection

• EM-RES-02: Resolver input, encoder emulation output (3 channels), 1 analog input

• EM-RES-03: Resolver input, 3 digital inputs, 2 digital outputs, 1 analog input, system bus

• EM-ABS-01: Absolute encoder input (Hiperface, EnDat 2.1, SinCos), 3 digital inputs, 2 digital outputs, 1 analog input, system bus, DC 5...12 V power supply output

Optional PC software

•VPlus for Windows with setup, terminal monitor

• Actual value window

• Scope function

Variant for functionality extension:

• Spindle (up to 1600 Hz output frequency)

• Yarn Winding machine

• Synthetic power supply

Accessories:

•Brake resistors

•Type BR: The brake resistors offer an inexpensive solution to dissipate generator power that occurs at deceleration. A thermal sensor for the brake resistor protects the resistor from overheating.

•Power choke type LCVS & LCVT: Power choke types LCVS (for single-phase power installation) and LCVT (for three-phase power installation) increase the overvoltage protection of the inverter and increase the system's EMC.

•Power filters type FTV: Depending on the application boundaries, certain EMC levels must be achieved. The power filters are a component to improve EMC behavior in a machine installation. -

Output

0 ... 599 Hz

-

POWER SIZE TYPES IN KW* (ANG210)

ANG 210- 01 | 1 | 0.25

ANG 210- 03 | 1 | 0.37

ANG 210- 05 | 1 | 0.55

ANG 210- 07 | 1 | 0.75

ANG 210- 09 | 1 | 1.1

ANG 210- 11 | 2 | 1.5

ANG 210- 13 | 2 | 2.2

ANG 210- 15 | 2 | 3

ANG 210- 18 | 3 | 4

ANG 210- 19 | 3 | 5.5

ANG 210- 21 | 4 | 7.5

ANG 210- 22 | 4 | 9.2 -

POWER SIZE TYPES IN KW* (ANG410)

ANG 410- 01 | 1 | 0.25

ANG 410- 03 | 1 | 0.37

ANG 410- 05 | 1 | 0.55

ANG 410- 07 | 1 | 0.75

ANG 410- 09 | 1 | 1.1

ANG 410- 11 | 1 | 1.5

ANG 410- 12 | 2 | 1.85

ANG 410- 13 | 2 | 2.2

ANG 410- 15 | 2 | 3

ANG 410- 18 | 2 | 4

ANG 410- 19 | 3 | 5.5

ANG 410- 21 | 3 | 7.5

ANG 410- 22 | 3 | 9.2

ANG 410- 23 | 4 | 11

ANG 410- 25 | 4 | 15

ANG 410- 27 | 5 | 18.5

ANG 410- 29 | 5 | 22

ANG 410- 31 | 5 | 30

ANG 410- 33 | 6 | 37

ANG 410- 35 | 6 | 45

ANG 410- 37 | 6 | 55

ANG 410- 39 | 6 | 65

ANG 410- 43 | 7 | 75

ANG 410- 45 | 7 | 90

ANG 410- 47 | 7 | 110

ANG 410- 49 | 7 | 132

ANG 410- 51 | 8 | 160

ANG 410- 53 | 8 | 200

ANG 410- 55 | 8 | 250

ANG 410- 57 | 8 | 315

ANG 410- 59 | 8 | 355

ANG 410- 61 | 8 | 400 -

POWER SIZE TYPES IN KW* (ANG510)

ANG 510- 51 | 8 | 160

ANG 510- 53 | 8 | 200

ANG 510- 55 | 8 | 250

ANG 510- 57 | 8 | 315

ANG 510- 59 | 8 | 355

ANG 510- 61 | 8 | 400 -

POWER SIZE TYPES IN KW* (ANG610)

ANG 610- 51 | 8 | 160

ANG 610- 53 | 8 | 200

ANG 610- 55 | 8 | 250

ANG 610- 57 | 8 | 315

ANG 610- 59 | 8 | 355

ANG 610- 61 | 8 | 400

Tại sao lại chọn chúng tôi???

=> Là một trong những đơn vị tiên phong trong ngành tự động hóa công nghiệp.

=> Đã và đang hợp tác với hơn 200 hãng uy tính khắp nơi trên thế giới - Và là đại lý của hơn 70 hãng

=> Đội ngũ kỹ sư được gửi đi đào tạo trực tiếp tại hãng hằng năm. Với kinh nghiệp dày dặn trong lĩnh vực sửa chữa các thiêt bị tự động hóa như: biến tần, servo motor, encoder, sensor, flowmeter, CPU, PC, Card, màn hình HMI, Modul, UPS, PLC,.... Đội ngũ kỹ thuật của chúng tôi sẽ hỗ trợ cho bạn 24/7 ( Tư vấn thiết bị, hướng dẫn - hỗ trợ lắp đặt, kiểm tra tình trạng - báo giá hoàn toàn miễn phí)

=> Thiết bị hay phụ kiện sửa chữa đều được nhập trực tiếp từ hãng, có COCQ chứng thực. Vậy nên bạn sẽ luôn được hỗ trợ về giá một cách tốt nhất.

=>Bảo hành 12 tháng với thiết bị cung cấp mới - 6 tháng với thiết bị sửa chữa - 1 đổi 1 nếu có lỗi phát sinh do nhà sản xuất

======>Liên hệ ngay với chúng tôi để được hỗ trợ.

Website: http://dichvusuabientan.com/

Gmail: tung@pitesco.com / nhat@pitesco.com

Mr Nhật: 0909.352.877

Mr Tùng: 0912300549

Mr. Tùng

Mr. Tùng